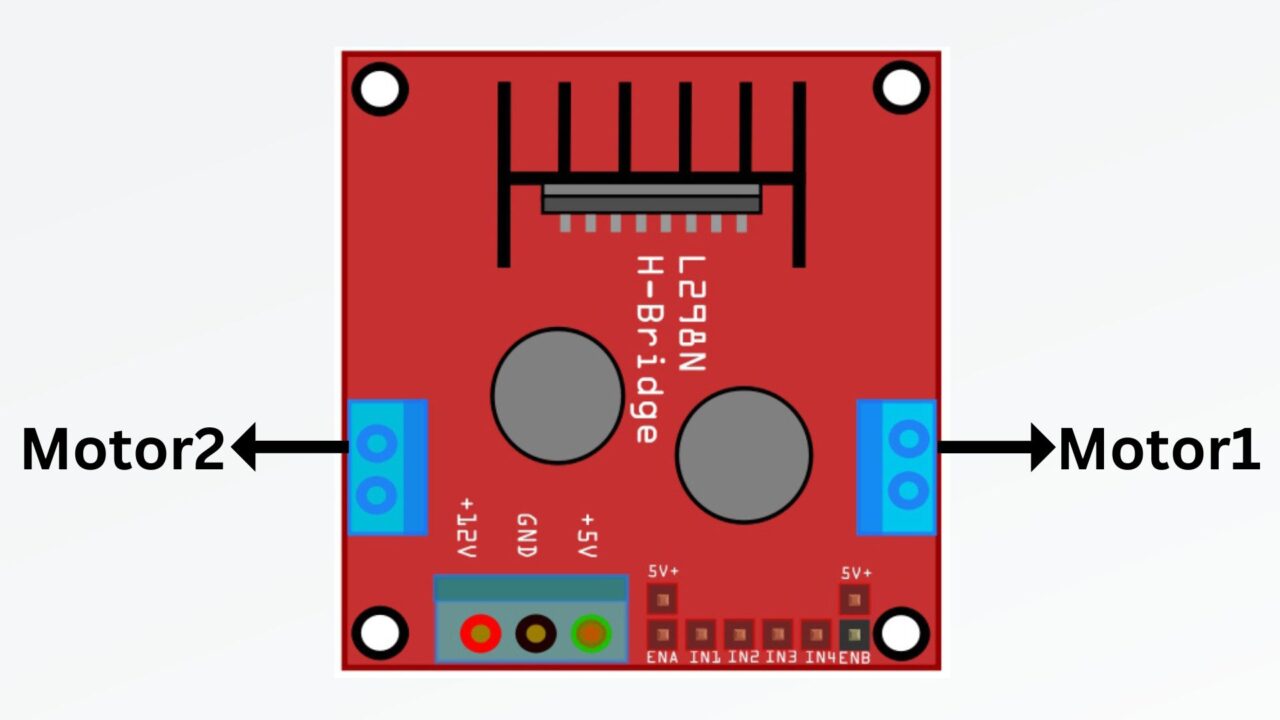

Design of the Circuit that was Used to Drive the Motors Circuit Diagram Learn how to control DC motors with an L298N motor driver module based on H-bridge configuration. See the pinout, schematic diagram, features and specifications of the L298N IC.

The L298n Motor Driver Module Circuit Diagram is a powerful tool for controlling motors in projects of all shapes and sizes. The circuit diagram allows users to control the direction, speed, and torque of DC and stepper motors with a simple, compact circuit board. Whether you are creating an automated robotic arm or a remote-controlled car

Basics of L298N Motor Driver Circuit Diagram

It is a popular and applicable MOSFET driver IC. The schematic diagram of the circuit demonstrated in figure-1. Step 4: Figure-2, Designed PCB Layout for the Motor Driver Schematic. I did not have the PCB footprint and schematic symbols of IR2104 [1] and IRFP150 [2] components. Therefore I use the SamacSys provided symbols [3] [4], instead

A DC Motor Driver Circuit Schematic is essentially an electronic circuit that is designed to provide power and control signals to a DC motor. This type of circuit typically consists of two parts- the power module, which supplies the energy required to run the motor, and the control module, which gives instructions to the motor such as speed Key learnings: Stepper Motor Driver Definition: A stepper motor driver is defined as a circuit used to drive or run a stepper motor, consisting of a controller, a driver, and motor connections.; Essential Components: Key components include a microcontroller, a driver IC like the ULN2003, and a regulated power supply.; Stepper Motor Controller: The controller must have at least 4 output pins

Bridge Motor Driver Circuit using MOSFET Circuit Diagram

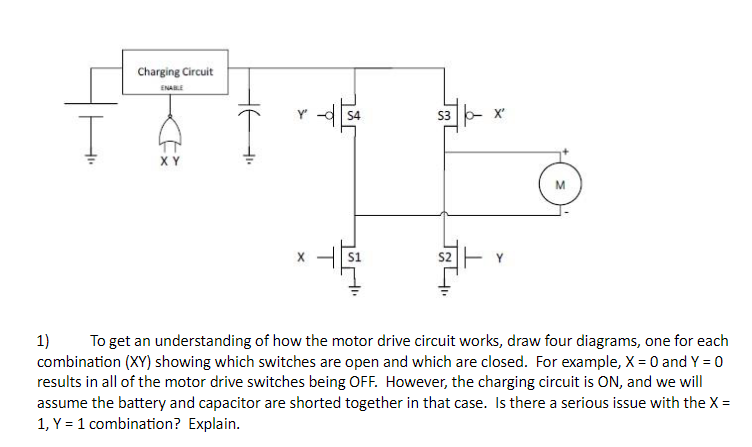

The H-Bridge Motor Driver Circuit . The complete circuit diagram for this H-Bridge using MOSFETs is given below: Working Explanation. 1. The 555 Timer. The timer is a simple 555 circuit that generates a duty cycle from around 10% to 90%. The frequency is set by R1, R2 and C2. High frequencies are preferred to reduce audible whining, but All of these components come together in a schematic diagram of a typical DC motor driver circuit. This diagram helps provide a clear understanding of the different components and how they interact to ensure smooth operation and optimal performance. By understanding the various pieces of the puzzle, you'll be able to troubleshoot issues and